MOLDINO -Ultra-deep fine-hole drills for high-hardened stee : EMSBHE-ATH | JSR GROUP

Ultra-deep fine-hole drills for high-hardened steel : EMSBHE-ATH

“From small hole EDM to drilling”

This marks the next step in the evolution of the Epoch Micro Step Borer H.

A total of 124 products ideal for various types of pin hole drilling

Do you have problems with EDM for deep, small-diameter pin holes?

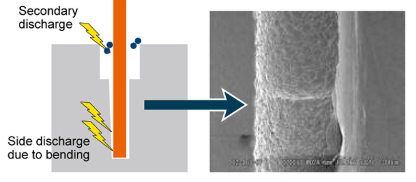

| When using small hole EDM on molds… |

|

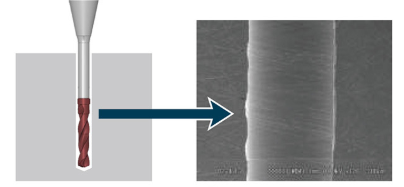

Drilling with EMSBHE |

|

・ Requires switching from milling machine to EDM. Machine can’t be left unattended |

・ Eliminates the need to switch from milling machine to EDM. Results in significant labor savings and allows unmanned operation. |

EMSBHE-ATH

Features of EMSBHE-ATH

Specially designed for micro-step drilling of deep, high-precision fine holes in high hardness steel

|

Special cutting edge shape for high hardness steel

Combines cutting edge rigidity and bite with smooth chip flow |

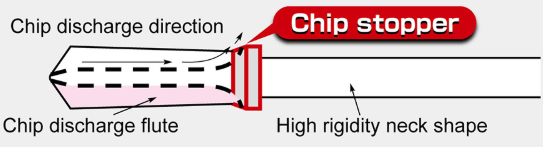

Chip stopper and high rigidity neck shape

|

Uses proven ATH coating for high hardness steel machining.

|

EMSBHEvolution

| 1 | Optimized surface treatment | |

| Helps extend and stabilize tool life when machining 60HRC class high hardness steel. | ||

| 2 | Significantly expanded tool diameter lineup | |

| Select the tool diameter to match the wire EDM and reamers to allow adjustment of tolerance for the subsequent process. | ||

| Ultra-deep fine-hole drills for high-hardened steel |

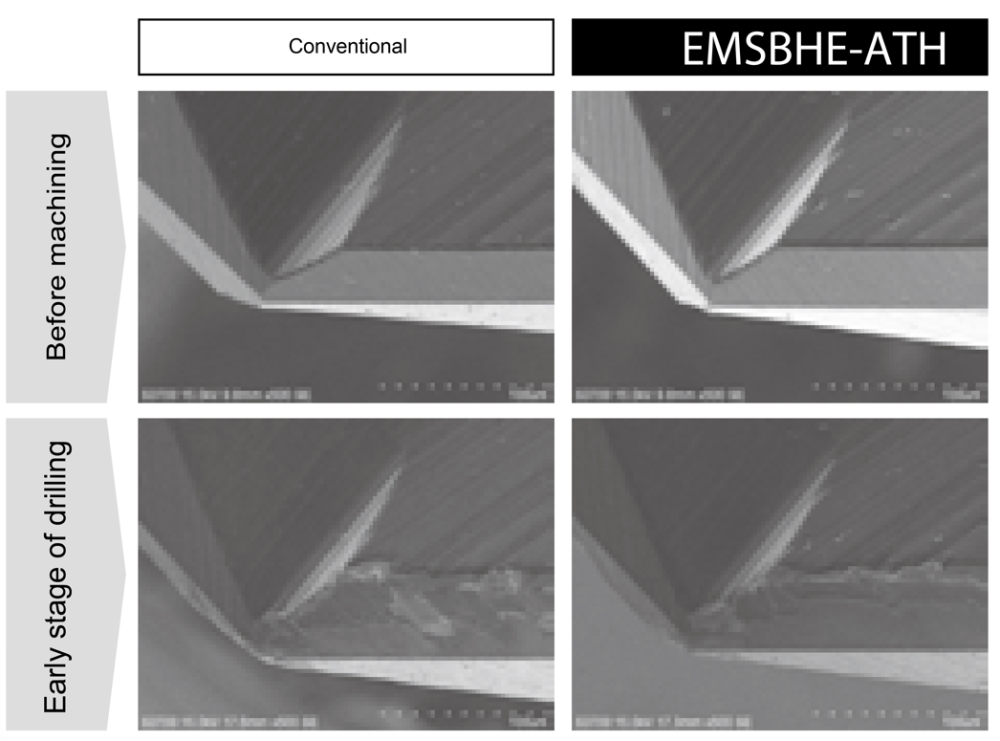

Tool:Under neck length 15mm Machine:MC(HSK-E25)Vertical MC Work material:SLD(60HRC) Cutting conditions:n=10,000min-1(vc=16m/min) vf=50mm/min(f =0.005mm/rev) Step feed:0.05mm Coolant:Water-based coolant G83 Peck drilling cycle

|

|

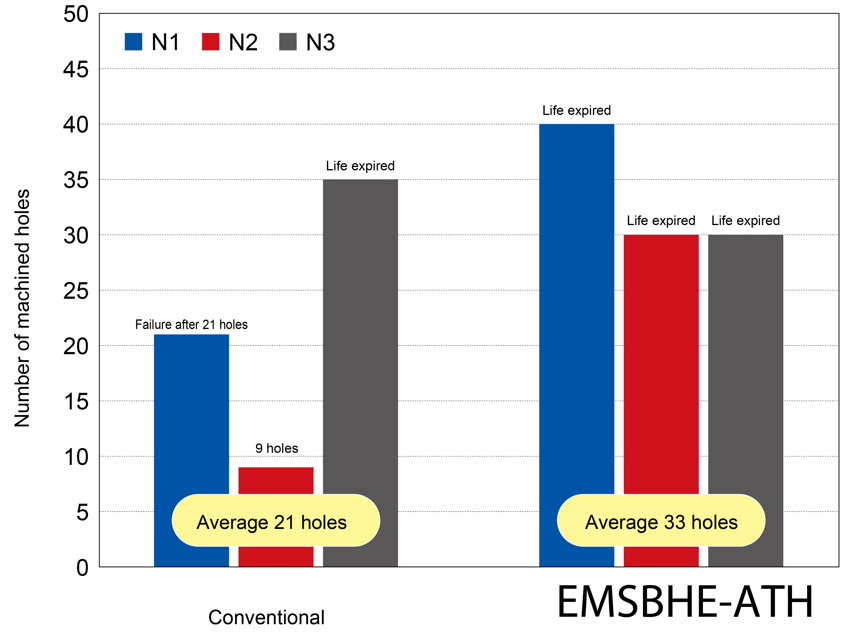

EMSBHE consistently reaches end of life without breakage. Improved machining stability with 60HRC class high hardness steel

| Comparison to conventional tools with PD613(58HRC) |

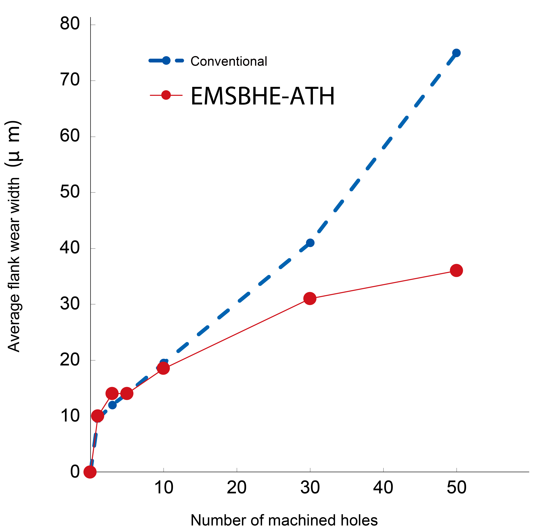

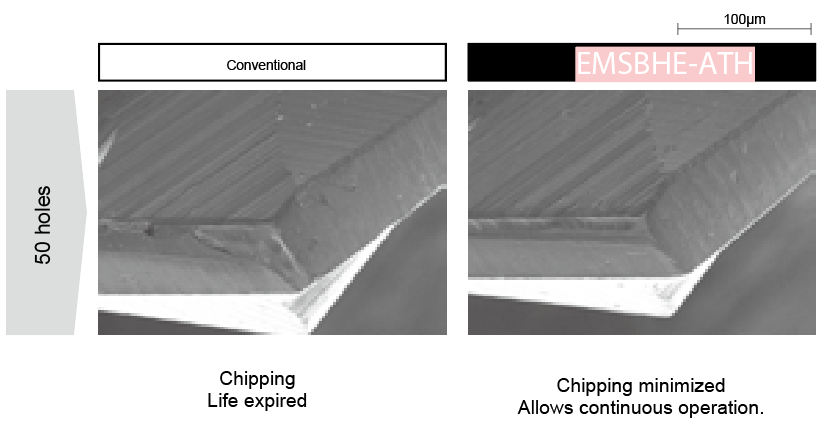

Tool:Under neck length 15mm Machine:MC(HSK-E25)Vertical MC Work material:PD613(58HRC) Cutting conditions:n=10,000min-1(vc=16m/min) vf=50mm/min(f =0.005mm/rev) Step feed:0.05mm Coolant:Water-based coolant G83 Peck drilling cycle

|

|

Flank wear reduced to less than half that of conventional tools. Allows continuous cutting—estimated life of at least 100 holes